Boiler

We protect your process

We have several hundred references using either our Low Cement Castables, precast linings and our unique HASLE Ceramic Vortex Finder in boilers.

HASLE supplies material/pre-cast elements to amongst others: Foster Wheeler, Metso Power and Ahlstom. The size of the boilers we have lined ranges from only a few MW units to units of several hundred MW taking up to more than 1,000 tonnes of high quality refractory materials.

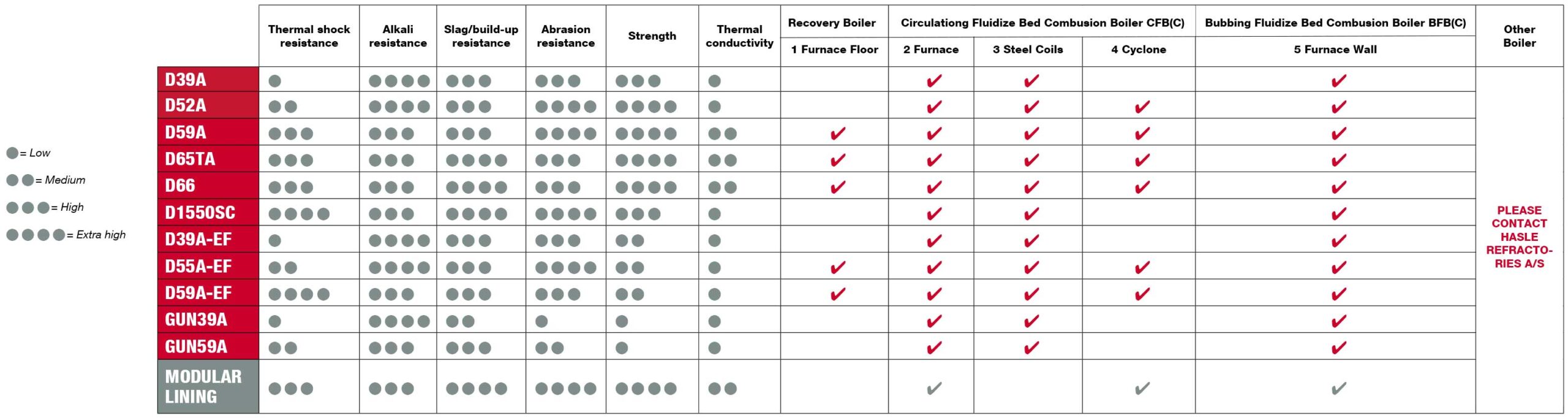

Find the right castable for your process

Click on the number by the various areas to see what problems typically occur. Find the number in the table below to see our recommended solution.

Furnace wall:

Abrasion, chemical attack and impact load from black liquor fuel.

Furnace:

Heavy abrasion and impact load from circulating fluidized bed process, especially kick out area.

Steel coils:

Even though this area is in a higher position than the furnace, it still gets abrasion and impact load from the circulating fluidized bed process problem.

Cyclone:

Abrasion and impact load problem, especially the cyclone wall which is directly attacked by bed material and hot gas from furnace.

Furnace wall:

Abrasion and impact load problem from bubbling fluidize bed process.

Furnace wall:

Abrasion, chemical attack and impact load from black liquor fuel.

Furnace:

Heavy abrasion and impact load from circulating fluidized bed process, especially kick out area.

Steel coils:

Even though this area is in a higher position than the furnace, it still gets abrasion and impact load from the circulating fluidized bed process problem.

Cyclone:

Abrasion and impact load problem, especially the cyclone wall which is directly attacked by bed material and hot gas from furnace.

Furnace wall:

Abrasion and impact load problem from bubbling fluidize bed process.

Download the chart to see the details of our recommended solutions for the individual areas of a cement plant.

“The diversity of fuels used for energy production is growing quickly, creating more harsh conditions in boilers.

Our low cement castables characterized by a very dense and strong matrix are developed to withstand the chemicals from these alternative fuels.”

– Michael Bladt, CEO